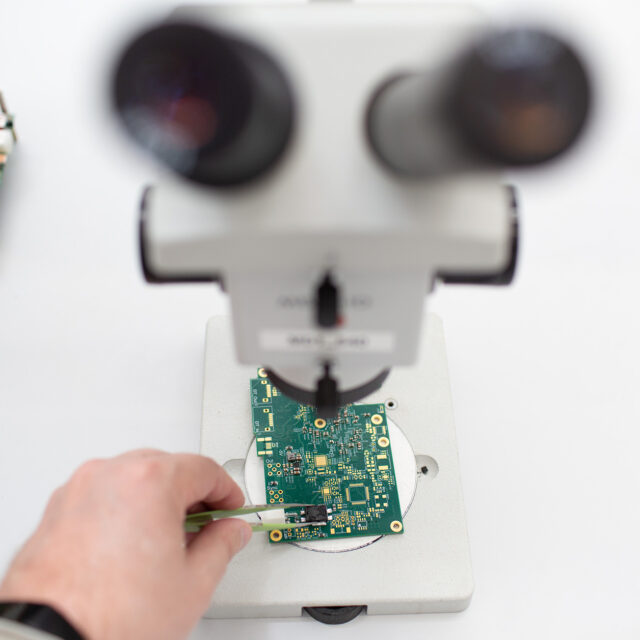

Every part is tested, inspected, and verified by our QC specialists.

Quality Control Levels Quality Control Levels

LEVEL 1

For every component received, our Level 1 inspection process includes the following:

Packaging and label inspection

Visual inspection of manufacturer packaging and labels to verify authenticity, condition, and compliance with industry standards.

Barcode verification

Scanning and checking barcodes to ensure accuracy, readability, and alignment with part and shipment information.

Part authenticity

Review and verification of manufacturer datasheets, drawings, and specifications to confirm part authenticity and technical compliance.

Digital imagery of components

High-res photos document each component’s markings, condition, and packaging — ensuring traceability and supporting customer verification.

Component surface testing

Surface testing checks for signs of resurfacing, sanding, or tampering on the component body and markings. This ensures authenticity and detects counterfeit or altered parts.

Marking permanency testing

This test verifies that component markings are original and durable by applying friction or solvents to the surface. It helps detect re-marked or counterfeit parts.

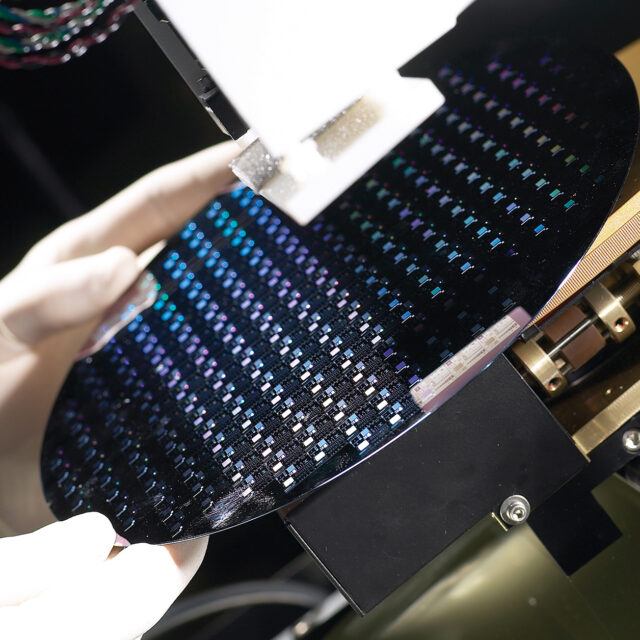

LEVEL 2

To further demonstrate our commitment to quality and product integrity, we have aligned ourselves with some professional testing organizations.

These third-party testing facilities certify components based on MIL and IDEA standards. Their services include:

- Incoming Visual Analysis

- Complete Lot Visual Analysis

- Electrical Testing

- Solderability

- Heated Chemical Test and Decapsulation

- X-ray Testing

Fixchips Global will only ship products determined to be authentic. There are no exceptions to this policy.